Reliable Damping Simulation of Highly Perforated MEMS by Physical Compact Modelling

Accurate and fast modeling of damping effects in high-end MEMS devices, like acceleration sensors (Fig 1) is a major challenge due to

- small feature sizes and large aspect ratios,

- complex device geometries & a generally very high number of perforations,

- multiple energy domains involved, e.g. Squeeze Film Damping (SQFD),

- low pressure packaging, leading to Knudsen Numbers Kn > 0.1.

In order to accurately predict damping in MEMS it is necessary to have models that

- scale with shape and size of the designed device,

- include external parameters, like surrounding gas or ambient pressure,

- account for transition regions between differently perforated areas.

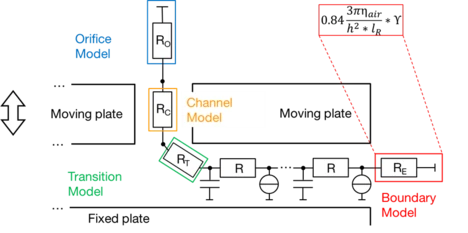

We approach this challenge by designing compact models and implement them in a finite Kirchhoffian Network, thus enabling cross-domain simulation (i.e. fluidic damping decreasing mechanical movement). This allows us to run the simulation in standard circuit simulators, speeding up the simulation process significantly.